- Home

- Mobile Dimensioning

- Warehouse Optimization

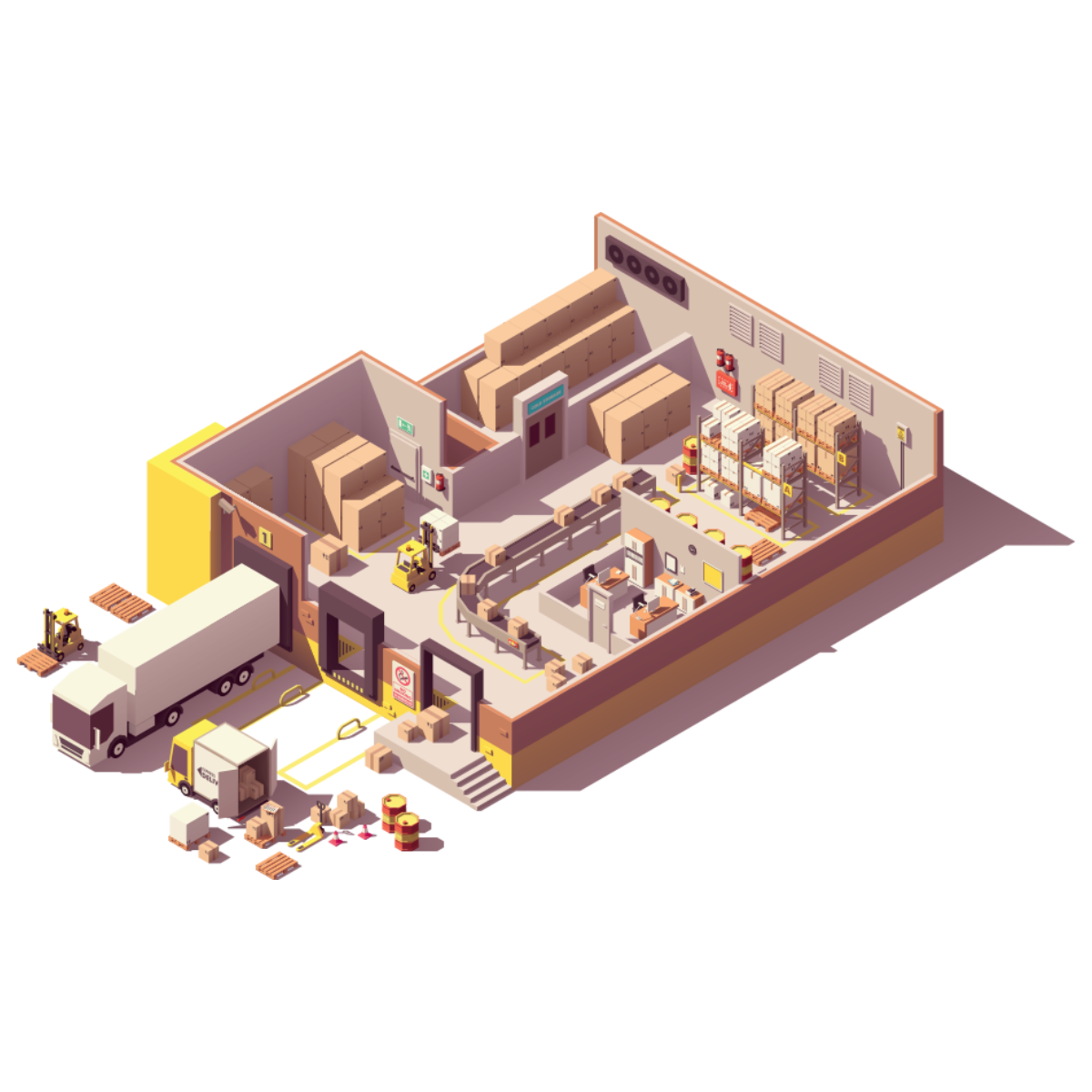

Streamline Slotting & Handling Efficiency with Space Utilization

Measure, Track & Optimize on the Spot

Mobile Dimensioning for Smarter Warehouses

Get precise product and dimension data instantly - where it matters most.

Mobile dimensioning turns every workspace into a data hub. Capture measurements, barcodes, and photos directly at the storage location. This keeps operations flowing with faster picking, smarter slotting, and smoother last-mile delivery—while reducing manual entry and errors.

With accurate data, you can plan storage strategically, maximize space, and adjust layouts without costly expansion. Better decisions, fewer mistakes, and higher throughput—right from your existing warehouse.Optimize Slotting

- Instant Data

- Smarter Flow

- Maximized Space

- Faster Decisions

Optimize Every Inch of Your Warehouse

Faster Operations. Smarter Space. Higher ROI.

Capture precise product data in real time to move goods faster and make every square foot count.

Mobile dimensioning captures measurements, weights, barcodes, and photos right at the storage location. This speeds picking and shipping while reducing errors and manual entry.

With accurate data, you can: plan storage efficiently, maximize space, and avoid costly expansions.

The result: lower costs, faster throughput, and measurable ROI—all using the warehouse you already have.

.png?width=295&height=241&name=simple%20mobile%20dim%20ios%20(1).png)

Calculate Your Mobile Dimensioning ROI

See how mobile stacks up. Our ROI calculator shows how switching from fixed systems to mobile dimensioning can save you up to 1/3 of the cost while working 3x faster. Backed by real-time data and real-world results, it’s the easiest way to visualize the time and money mobile can save your operation—right where the work happens.

FAQ

Got Questions? We've Got Answers.

Everything you need to know about mobile dimensioning and warehouse optimization.

What types of data can I capture with mobile dimensioning?

You can record product dimensions, weights, barcodes, photos, and other key attributes - all directly on-site without moving items.

Easily tailor data collection with up to 12 customizable fields—designed around your organization’s needs.

Do I need a fixed workstation to use this solution?

No. Our mobile system works wherever your products are located - warehouse, shop floor, or in the field - eliminating the need for dedicated measurement stations. This frees up even more space for your organization!

How does this improve warehouse efficiency?

Mobile dimensioning improves warehouse efficiency by capturing accurate item measurements—instantly, right at the product’s location. This eliminates the need to move items to a stationary system, saving time and labor. With precise dimensions flowing directly into WMS or slotting software, warehouses can:

-

Optimize storage space – maximize rack and bin utilization by assigning the right location the first time.

-

Improve slotting strategies – ensure fast-moving products are placed in optimal spots for faster picking.

-

Enhance load planning – know exactly how products fit together for pallets, trucks, and containers.

-

Reduce errors and rework – no manual entry means fewer mistakes and less wasted space.

-

Increase throughput – employees spend less time measuring and more time moving product.

In short, mobile dimensioning speeds up operations, ensures data accuracy, and helps warehouses make the most of every cubic inch—leading to higher productivity and lower costs.

Can this integrate with my existing warehouse management system (WMS)?

Yes. The solution is designed to sync with most WMS and ERP platforms, ensuring consistent, up-to-date product data across your operations.

How quickly can data be captured?

Data can be collected in seconds per item - from barcode scans and weight recording to photos and dimensional measurements - without disrupting workflow.

Does it reduce data errors?

Absolutely. mobile dimensioning powered by AI significantly reduces errors. Traditional manual measurement methods rely on tape measures, rulers, or human-entered data, all of which introduce variability and mistakes. AI-driven mobile dimensioning changes that by:

-

Automating measurement with computer vision algorithms – The camera uses advanced AI models trained to detect object edges, shapes, and irregularities, ensuring highly accurate readings regardless of item size or orientation.

-

Correcting distortions through coding logic – AI coding compensates for perspective, angles, and lighting differences, preventing skewed or inconsistent measurements.

-

Standardizing data capture – Measurements and metadata are instantly coded into structured fields, removing human error from manual entry.

-

Learning and improving over time – AI models continually refine accuracy as more items are scanned, recognizing patterns and reducing repeat errors.

-

Integrating directly into WMS/PIM systems – Automated coding ensures the right data flows seamlessly into existing platforms, preventing mismatched records or duplicates.

In short, by combining AI-driven computer vision with intelligent coding rules, mobile dimensioning creates a repeatable, precise, and error-resistant process that humans alone can’t match.

If I already have a fixed system, can I still add mobile dimensioning?

Absolutely. Mobile dimensioning complements fixed systems by offering flexibility where fixed units can’t reach. It’s ideal for overflow, large or irregular items, or areas of the warehouse not covered by your existing setup.

Will I be out more money if I add mobile dimensioning after investing in a fixed system?

No - mobile dimensioning actually helps maximize your investment. By filling coverage gaps, reducing bottlenecks, and capturing data faster, mobile units extend the value of your fixed system and accelerate ROI. See for yourself with our helpful ROI Calculator.