- Home

- Mobile Dimensioning

- Mobile Dimensioning

Discover Mobile Dimensioning

Product Data, Captured Anywhere

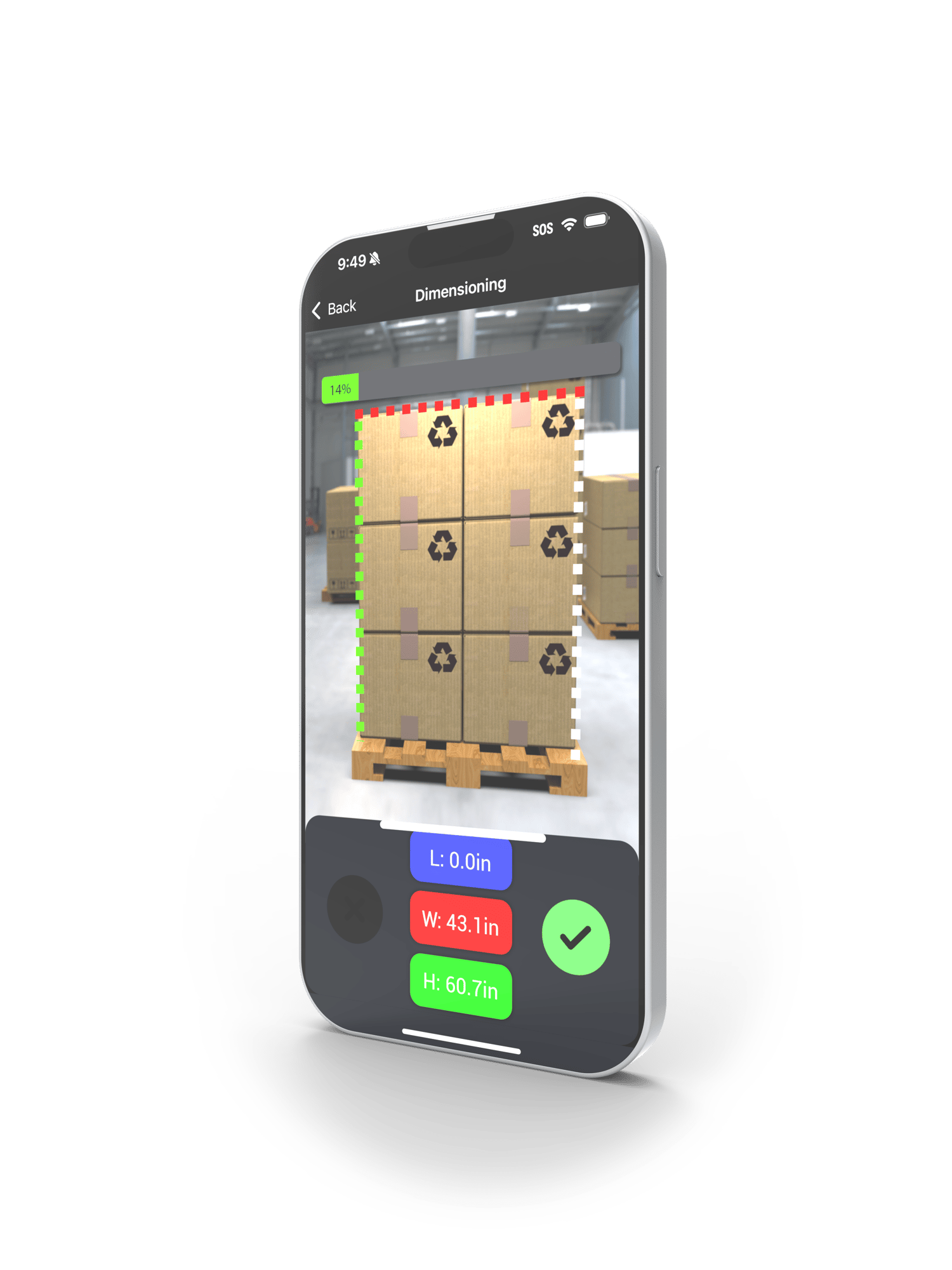

What is Mobile Dimensioning?

Quickly capture dimensions, weight, photos, and more—right at the product’s location. No fixed station needed.

Mobile dimensioning is the easiest way to capture accurate product measurements using a mobile device like a tablet or smartphone—no need to bring items to a fixed station. In just seconds, you can scan, measure, weigh, and photograph items directly at their location. It’s fast, flexible, and built to simplify warehouse, shipping, and logistics workflows.

Explore Our Mobile Dimensioning and Data Collection Apps:

- xPIM+ on iOS Pro Devices

- xPIM on iOS & Android

- xDIM on Windows

- xScale

- Photo Capture

Increase Mobility & Agility

Automatically measure items (lxwxh) and collect master item data data at product location, no more moving to-and-from a fixed dimensioner system. Capture all pertinent item data in a single application.

Improve ROI & Cut Costs

Reduce shipping surcharges with accurate, mobile dimensioning—no more walking back and forth to a fixed station. Speed up your workflow, unlock density-based pricing, and improve NMFC code accuracy for measurable ROI and long-term savings.

Optimize Space & Time

Enhance warehouse slotting and storage optimization with precise product data. Improve TI-HI pallet configurations and spacing accuracy to support automation planning and robotics. Ideal for LTL carriers, 3PLs, and high-throughput distribution centers.

Modernize Workflows

View data in real time and integrate with existing WMS or PIMS system. Segment and identify items quickly and accurately with Computer Vision, Artificial Intelligence and Machine Learning.

White Paper: Mobile Dimensioning in Modern Logistics - 2025 ROI Outlook

Cut SKU capture time by 70% and cost by 80%—see how MobileDemand’s patented tech outperforms fixed systems in speed and savings.

App

xPIM on iOS

Download app for your iPhone Pro and iPad Pro

App

xDIM on Windows

Powered on our xTablet T1175 Rugged Tablet

App

xPIM on Android

Download app for your Android

App

xScale

Capture Weight On-The-Go

The xScale App connects via Bluetooth to a portable, rugged scale, letting you easily capture and copy weight data into your WMS, ERP, or PIM systems. The xScale S200 integrates smoothly with xPIM and xDIM, making it a practical, mobile add-on to your product data collection workflow.

App Feature

Photo Documentation

A Desired Feature Found in xPIM and xDIM Apps

Application Main Features

Do More With Our Applications

PC Dock

With xDIM running on our xTablet T1175, your department gains a fully capable PC system—delivering more than just mobile dimensioning.

High Res Photos

With your iPhone Pro or iPad Pro running xPIM, one can capture up to six additional high-resolution photos. These images support cataloging for marketing and streamline order verification for your picking team.

Deployment Breeze

xPIM’s intuitive interface enables your team to start capturing data quickly and efficiently.

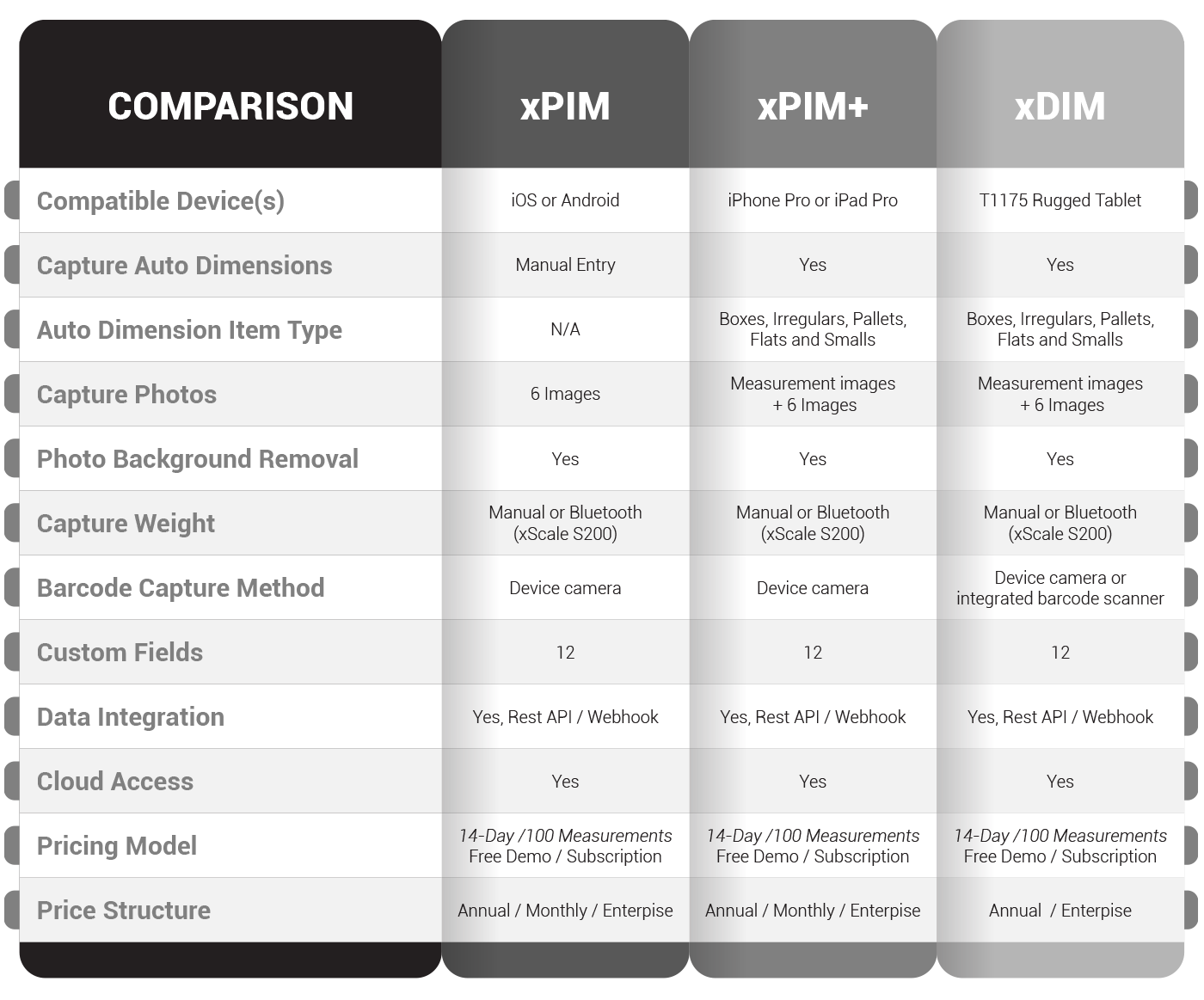

Compare MobileDemand's Data Capture Apps

From fast, mobile dimensioning to full item-level detail collection, our suite of apps helps streamline your warehouse operations. Use the chart below to find the right fit:

FAQ

Common Questions About Mobile Dimensioning

What is mobile dimensioning?

Mobile dimensioning allows you to instantly capture item measurements using a mobile device or rugged tablet—no tape measures or stationary cubing machines required. With xDIM and xPIM+, users can measure boxes, pallets, flats, and irregular items right at their location using advanced computer vision and AI.

What's the difference between xPIM and xPIM+?

See the full comparison here.

What types of items can it measure?

You can measure nearly anything, anywhere:

- Boxes / Parcels

- Oversized Boxes

- Irregular Items

- Small Items

- Pallets

- Flat-Packed

- Bagged Items

- And More!

Do I need special hardware to use it?

Yes—mobile dimensioning software must run on some sort of mobile device. Our mobile dimensioning solutions use the following:

xDIM - xTablet T1175 Rugged Tablet with an attached Intel RealSense 3D depth camera.

xPIM+ only runs on any iPhone Pro or iPad Pro using LiDAR technology. The (+) in xPIM+ indicates the upgrade for auto dimensioning.

xPIM runs on any iPhone or Android device. Reminder, xPIM does not do auto dimensioning, but has the field for you to enter the dimensions manually.

These are purpose-built for capturing dimensions on the go, anywhere in the warehouse and field. No bulky cubing stations needed!

Where can I use it?

Anywhere. Measure products at receiving, on the warehouse floor, in reverse logistics, or even at the point of loading. Mobility is key, and xDIM and xPIM+ are built to go where your product is.

Is it faster than manual measurement?

Yes—dramatically. Dimensioning with xDIM or xPIM+ takes just seconds per item or pallet, reducing bottlenecks and speeding up workflows by eliminating manual data entry.

What happens to the data after measuring?

All captured data—including dimensions, photos, weight, and barcodes—can be exported or integrated into your existing WMS, ERP, or PIM system. It's easy to centralize SKU-level details.

Why should I automate my dimensioning process?

Automating dimensioning saves time, prevents manual entry errors, and avoids costly reclassification fees from carriers. Tools like xPIM+ and xDIM make the process seamless by instantly capturing details with a tap.

Does it help with freight classification (NMFC codes)?

Absolutely. Accurate pallet dimensions captured at the dock help validate NMFC classifications, reducing chargebacks and costly reclassification fees.

Is training required to use it?

xPIM+ requires minimal training—its intuitive design lets warehouse teams start using the app within minutes of downloading it from the App Store. xDIM is also easy to learn, with a quick setup once your tablet arrives.

How much does it cost and what’s the ROI?

ROI is typically fast, see for yourself here. Customers report time savings, fewer reclasses, improved data quality, and smoother WMS workflows—making the investment pay for itself quickly.