Mobile Dimensioning System

Show Me What's Possible:

Redefining Warehouse Workflows

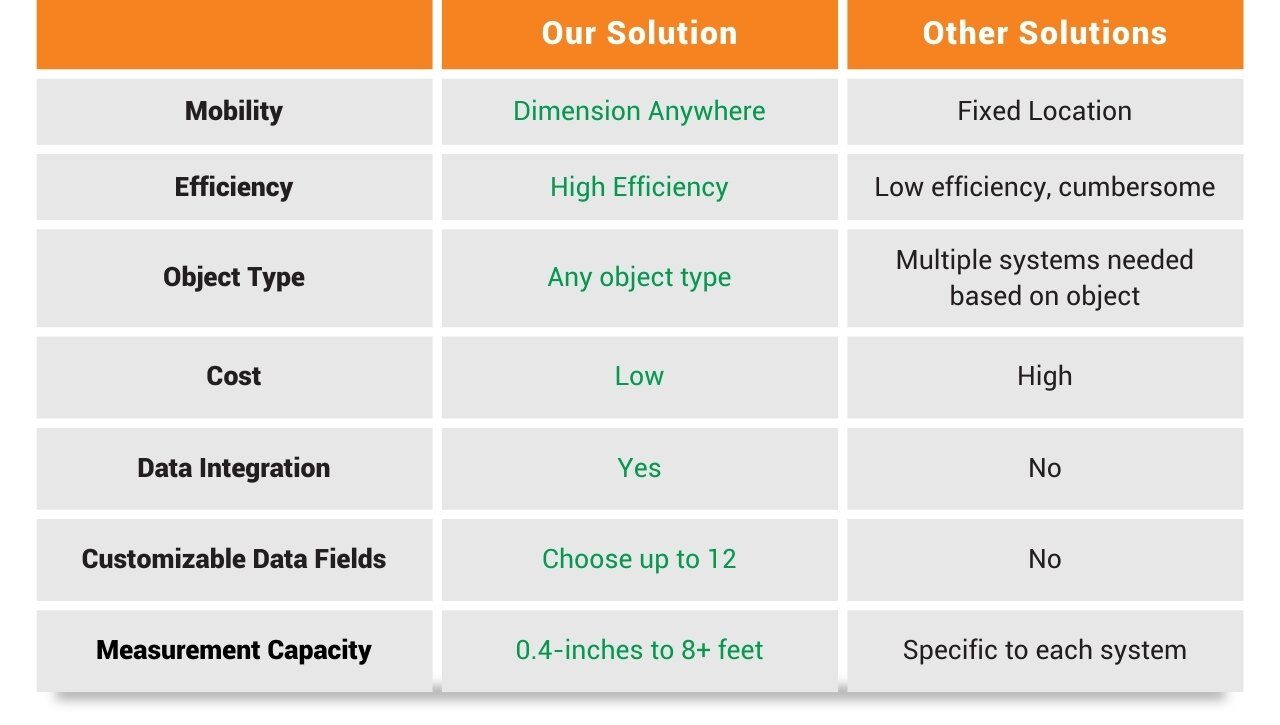

Mobile vs. Fixed Dimensioning

Ditch the fixed dimensioner. Go mobile with xDIM.

Mobile dimensioning system quickly and accurately captures dimensions of boxes, irregular items, and pallets, anywhere in the warehouse. This AI-powered, mobile solution enables an entirely new workflow with the ability to capture dimensions, weights, and item pictures at the product location, even at the upper levels of the shelving.

Stationary dimensioning systems are limited in speed, flexibility, and adaptability in dynamic warehouse environments. Gone are the days of bringing items to-and-from a rarely used, dust covered stationary dimensioner or scale in the back corner of the warehouse.

The versatility, efficiency, and accuracy of mobile dimensioning sets a new standard in the industry, dimensioning 40% faster than its stationary counterparts.

Dimension anything, anywhere.

.png?width=295&height=241&name=simple%20mobile%20dim%20ios%20(1).png)

See Your Savings by Switching to Mobile

See how mobile stacks up. Our ROI calculator shows how switching from fixed systems to mobile dimensioning can save you up to 1/3 of the cost while working 3x faster. Backed by real-time data and real-world results, it’s the easiest way to visualize the time and money mobile can save your operation—right where the work happens.

White Paper: Mobile Dimensioning in Modern Logistics - 2025 ROI Outlook

Cut SKU capture time by 70% and cost by 80%—see how MobileDemand’s patented tech outperforms fixed systems in speed and savings.

Additional Key Features

Photo Documentation / Background Remover

xDIM's photo documentation feature, combined with our background remover in Insight, makes cataloging much easier and supports efficient picking verification and receiving claims.

Master Data Collection

xDIM provides a single place to record all necessary product information. When items are too large for a stationary dimensioner, workers may resort to using a tape measure and pen-and-paper to record dimensions, leading to potential inaccuracies and inconsistencies between users. xDIM's advanced technology guarantees precise and consistent measurements every time, regardless of the operator, reducing human error and enhancing data integrity.

Multi-Mode Dimensioning

The ability to dimension boxes, irregular items and pallets distinguishes xDIM from traditional stationary dimensioners, which are limited to a single type of dimensioning. Having a single system capable of dimensioning any item entering the warehouse streamlines the workflow and simplifies the dimensioning process.

Reduce Human Error

When items are too large for a stationary dimensioner, workers may use a tape measure and pen-and-paper to record dimensions which can lead to inaccuracies and inconsistencies between users. xDIM’s advanced technology ensures consistent and accurate measurements every time, regardless of who operates the system, minimizing human errors and improving data integrity.

Real-Time Data Capture

By integrating seamlessly with existing warehouse management systems, xDIM enables real-time data capture and analysis. Instant measurement recording and transmission to the central database empowers warehouse managers to access accurate dimensional information promptly, facilitating informed logistics and operational decision making.

.png)

What are others saying?

Feedback we often hear from the field...

Dimensions in the Air

"From high in a lift to a far corner of the warehouse, we're able to collect master item data right at the products location."

Game-Changer

"No more clunky equipment - xDIM mobile dimensioning is a game-changer for our team!"

Efficient

"xDIM is faster, more accurate, and way more convenient than our old method."